Electrostripping

Electrostripping is basically the opposite of Electroplating. Instead of using electricity to add a layer of metal plating to a base metal, Electrostripping is used to remove a layer of metal plating.

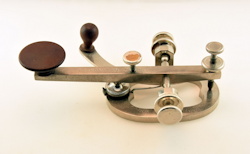

Although Electrostripping is rarely needed when restoring a key, there is one particular case where it is useful. Sometimes you may encounter an early key, maybe from the 1800's, that has been chrome plated by someone who thought it would look nice. However, chrome plating was not invented until well after 1900. So in reality, a chrome plated landline key is not historically accurate, and actually looks ridiculous !

Chrome plating is applied in a 3 step process. First, a flash layer of Copper, followed by a layer of Nickel, and finally a layer of Chrome.

Electrostripping a Chrome plated key will leave the key Nickel plated, which looks far more authentic than one which is Chrome plated.

To do the electrostripping, you will need a brush plating kit, a DC power supply set to 12V, and some Sodium Hydroxide solution (also known as Lye, the active ingredient in drain cleaner). Do not use drain cleaner however, because it is not a strong enough solution. The correct solution can be obtained from Caswell Plating.

Detailed instructions for using the brush plating kit can be found on my Electroplating page. Pour some Sodium Hydroxide solution into a cup. I recommend wearing rubber gloves when working with Sodium Hydroxide as it is caustic and can burn your skin. Attach the POSITIVE side of the 12V supply to the part you want to electrostrip. Connect your plating brush to the NEGATIVE side of the supply. (Note that is is the opposite of how you connect your power supply when doing electroplating). Dip the brush into the solution and rub it across the metal part. You will see a yellowish residue appear on the brush. This is the chrome plating coming off the part. Dip your brush into a cup of clean water frequently to remove this residue. When you don't see any more yellow residue appear, that means only Nickel plating remains. Rinse the part thoroughly when finished to remove any remaining Sodium Hydroxide.

|

|

|

Above on the left is a picture of an early landline key by William Lundberg, San Francisco, Ca. 1863. Someone had the key Chrome plated. Notice the bluish cast of the Chrome plating. Also, the spring tension adjustment screw has a some raw brass exposed where the plating has peeled off. On the center and right is the same key after electrostripping. All parts of the key have been stripped except for the contact pedestal on the base, which is still Chrome plated. You can see the difference in color between the Nickel and Chrome plating !